WFM Micro Fine Vibration Grinder

Products Details 1.MAIN USE: The machine is effective for any fiber, high toughness, high hardness or a certain degree of water content of the material can be effectively crushed, especially for Chinese medicine cell wall and other purposes...

Date:2019-12-27 01:13:47

Publisher:admin

Inquire Now

Date:2019-12-27 01:13:47

Publisher:admin

Products Details

1.MAIN USE:

The machine is effective for any fiber, high toughness, high hardness or a certain degree of water content of the material can be effectively crushed, especially for Chinese medicine cell wall and other purposes designed to improve the bioavailability of drugs and the use of conventional methods can not meet the requirements Fineness of the material.The machine can be applied to the following materials:ganoderma lucidum,mushroon,instant coffee,etc.

2.MAIN FEATURE:

The machine uses the optimized vibration parameters to make the medium produce vibration shock, and at the same time rotation and revolution, so that the object is subjected to positive impact and at the same time by high-strength cutting effect, so high-speed high-energy crushing, the machine has high efficiency, Pollution and crushing temperature controllable characteristics, and can achieve more than two kinds of materials, precision mixing, composite and coating operations.

You can set the vibration grinding time for control the final powder size fine or not fine. If you want to grind micro fine, you can set 45mins or more. If your expected final powder is not so fine, you can set only 10mins or less.

Very low noise cause the noise reducer room closed the main grind part

Disinfection system.

With water cooler, helps machine more efficient.

Time control system, more easily operation.

3.WORKING PRINCIPLE:

The machine is a horizontal vibration mill, the material from the hopper into the crushing chamber, the vibration will crush the indoor grinding rod and material collision, grinding and get crushed, the machine is equipped with water cooling device, can control the temperature of the crushing chamber, machine According to "GMP" standard design, the use of stainless steel manufacturing, equipment in the state of full sealed operation, no dust flying, no environmental pollution.

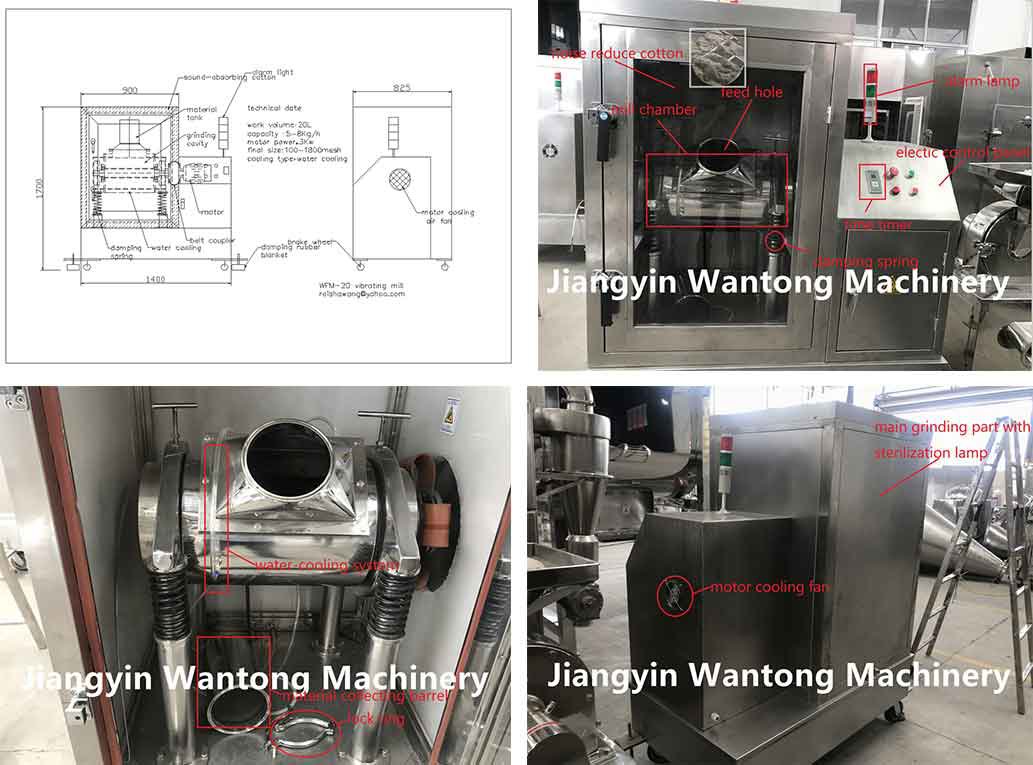

4.TECHNOLOGY DATA (only for reference data, can customized)

| MODEL | 20 | 50 | 100 |

| Load volume(L) | 20 | 50 | 100 |

| Capacity(kg/batch) | 2-10 | 10-30 | 20-60 |

| Final powder fineness | 200-3000mesh | ||

| Cooling method | Water cooling | ||

| Power(kw) | 2 | 7.5 | 11 |

|

Overall size(mm) (L×W×H) |

1250×900×1400 | 2100×1000×1600 | 2850×1500×1800 |

| Weight(kg) | 500 | 950 | 1500 |

Vibrating mill Configuration

| NAME | Qty. | specification | supplier |

| Electric motor | 1 | Upon model | Jiangyin |

| Bearing | 2 | NSK | |

| Bearing seat | 2 | A3 | Self |

| Belt | 4 | Rubber synthesis | Jiangyin |

| Electric appliance | 1set | ZHENTAI | |

| Cylinder | 1 | ss304 12mm | Self |

| Vibrating stick | ss304 | WUXI | |

| Base seat | 1 | 10mm steel channel outside cover ss304 | Self |

| Noise remove box | 1 | Soundproof material with soundproof cotton outsourced ss304 | Self |

| Casters | 4 | WUXI | |

| Barrel | 1 | 2mm304ss | Self |

| Hoop | 1 | 304ss | WUXI |

| Eccentricity block | 4 | A3 | Self |

| principal axis | 1 | 45steel | Self |

| lamp | 1 | Ultraviolet lamp | WUXI |

| lamp | 1 | LED lamp | WUXI |

| lamp | 1 | Alarm lamp | WUXI |

5.OPERATE REQUEST

After the machine reach the working time, can take simple to check, if reach requirement, rotate the working chamber, make the charge barrel underneath, and let the machine jog mill, the final powder will come out into the small barrel, loose bolt and take the final powder, in addition, during the working, the sterilization light should be on, so that keep the working room no pollution, after working, cleaning machine, and install everything, in order to use next time.

6.OPERATION NOTES

1:Before working, should be check all screw if tight, avoid loose, fall off during working

2:The main axis rotate must be the right, otherwise it will damage the motor, and probably harmful the human

3:Check the electric appliance if complete, if have electric wire exposed or electric leakage

4:Before feeding material, should be make sure the material not include other things like metal, avoid to damage the vibration bar or damage the motor

5:The machine bearing should often feed lubricating oil. So that keep the machine smoothly and normal working

6:Should check the vibration bar in time, if found damage, should change it

7:The machine should be install on the smooth of ground

7.OPERATE STEPS

1: First connect the electric, when the power light light, its meaning already have power

2: Press the crush on, let the crusher working

3: Open the sterilization switch

4: Setting the working time

8.ATTENTION

1: The master stop is mainly used for after working, press it, the machine will stop all work, or meet emergency circumstance , use this

2: The jog mill used for discharge or cleaning

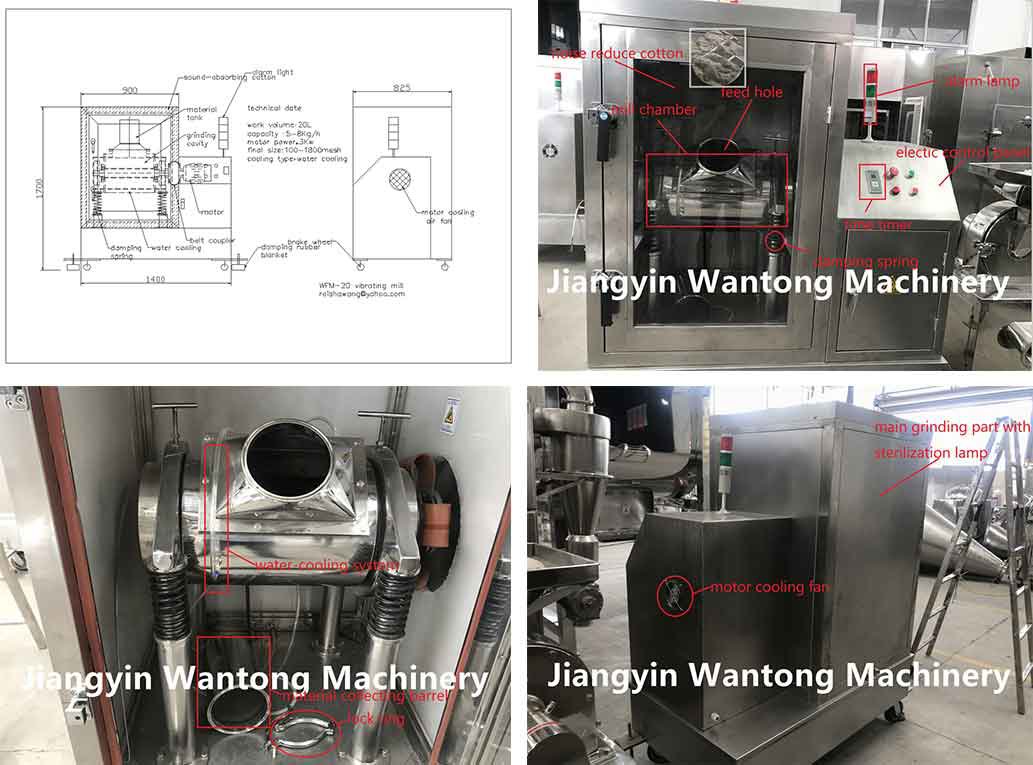

Products Picture

Products Picture

MACHINE PICS&LAYOUT

The Sugar Mill Grinder include howe reduce cotton, feed hole, motor cooling far etc.